Top 10 Inventory Management Techniques: A Comprehensive Guide

We will explain top inventory management techniques with examples and key features in this article. So, you can discover top methods and choose the most suitable one to manage your stocks effectively.

Table Of Content

I. What is Inventory Management?

II. What does it mean with Inventory Techniques?

III. Top Inventory Management Techniques

- Just-In-Time (JIT)

- Analysis of ABC

- FIFO, LIFO or Weighted Average

- Economic Order Quantity (EOQ)

- Safety Stock

- Six Sigma

- Drop shipping

- PAR Levels

- Reorder Point Formula

- Perpetual Inventory Management

IV. How to track my Inventory?

I. What is Inventory Management?

Keeping track of inventory is an important part of any business that sells physical goods. Because, an effective inventory management means keeping an eye on how things move from factories to warehouses and then to stores where they are sold. The main goal of inventory management is to make sure that there is always enough stock to meet customer needs and not too much stock that takes up space and costs money.

Businesses can cut costs, improve cash flow, and make more money by managing their inventory well. It includes many tasks, like ordering, storing, keeping track of, and managing inventory. Companies can avoid running out of stock or having too much of it by using good inventory management techniques. This way, they can always meet customer expectations.

II. What does it mean with Inventory Techniques?

Inventory techniques are the plans and strategies that are used to keep track of and manage stock well. These techniques help companies figure out how much stock to keep on hand, when to reorder, and how to keep track of their inventory levels.

Also, there are different ways to manage inventory, and each has its own benefits and best situations for use. That’s why, the type of business, the products, and the size of the operations all affect which technique is best.

More effective inventory management will bring lower costs & happier customers.

So, let’s discover the key methods for you to manage your stocks more effectively.

III. Top Inventory Management Techniques

Now, we’ll explain key inventory management techniques with simple and easy to understand examples:

1. Just-In-Time (JIT)

When you use just-in-time (JIT) inventory management, you only order and receive inventory when you need it for production. So, this method cuts down on holding costs and the amount of capital that is stuck in inventory.

But JIT needs accurate predictions of demand and dependable suppliers to keep from running out of stock.,

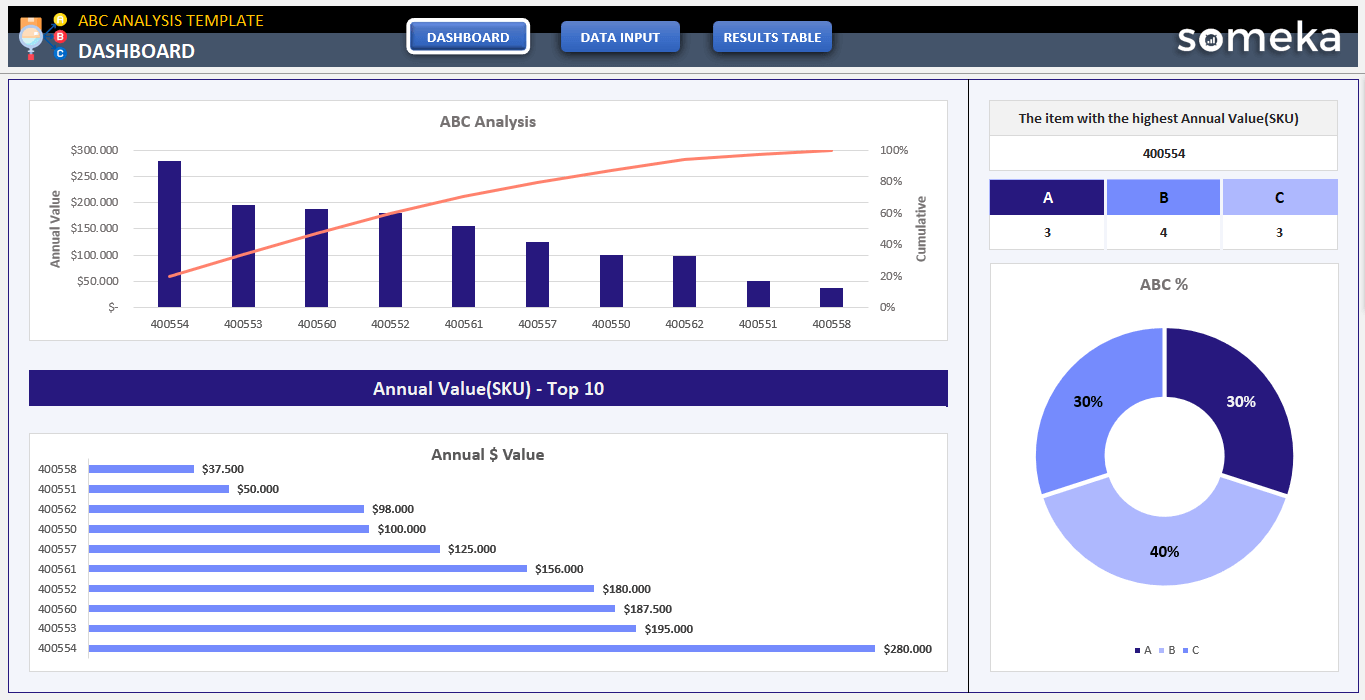

2. Analysis of ABC

Basically, ABC analysis is a way to divide inventory into three groups based on how important each one is:

- A-items are expensive items that don’t sell very often.

- B-items are products with a moderate value that don’t sell very often.

- C-items are low-value items that are bought a lot.

This method helps companies organize their management work so that the most important things get the most attention.

>> Download ABC Analysis Template

For an effective ABC Analysis, you should:

- Calculate the values of your items/products

- Sort your items according to their value

- Define your ABC rates

- Classify your items

Our ABC Template will help you to group your inventory according to ABC rule with automated formulas, sorting and formatting. Also, a professional dashboard is included.

3. FIFO, LIFO or Weighted Average as Inventory Management Techniques

One of the most important decision on stock strategy is defining the stock in and out directions while calculating the inventory values. The FIFO, LIFO and weighted average are the most common calculation methods.

What is FIFO?

Firstly, when you use the FIFO (First In First Out) to figure out how much an inventory is worth, the oldest items are sold first. This method works well for goods that go bad quickly or have expiration dates because it makes sure that older stock is used up before it goes bad.

What is LIFO?

Secondly, the LIFO (Last in Last Out) assumes that the newest items are sold first. In times when prices are going up, LIFO can be helpful because it lowers taxable income by matching recent higher costs with current revenues.

What’s weighted average as an inventory management technique?

Thirdly, the weighted average is calculating your stock value by calculating all the total value of stocks and dividing it to the total quantity.

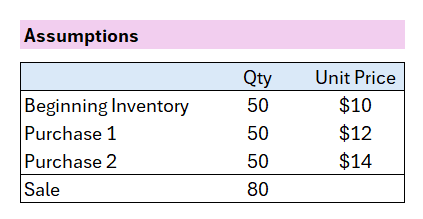

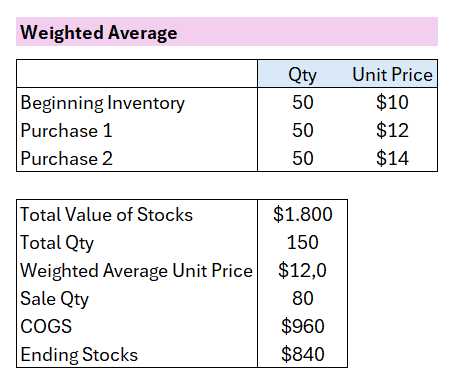

Let’s assume we have 50 unit inventory with a unit price of $10. Firstly, we’ll buy 50 more units with a unit price of $12, and then another 50-unit lot with a unit price of $14. Then, we’ll sell 80 units. Now, let’s calculate COGS (Cost of Goods Sold) and ending inventory values according to these three different methods.

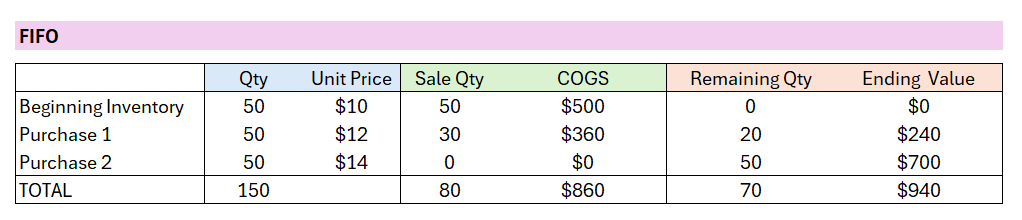

With FIFO, the sold quantity will begin to drop from the oldest stocks. So, the first 50 units will come from the beginning inventory, and the remaining 30 units will come from the Purchase 1 inventory. Then the COGS will be $860 and the Ending Value of Stocks will be $940.

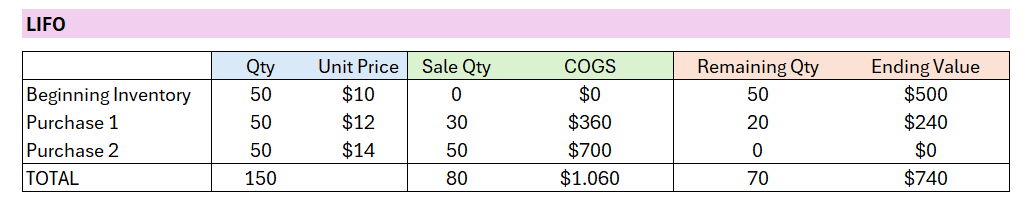

On the other hand, with LIFO, the first 50 units will come from the newest stocks, in this case from the Purchase 2 stocks, while the remaining 30 units will come from Purchase 1. Then, the COGS will be $1.060 and the ending stocks will be $740.

Lastly, with the Weighted Average as an inventory management technique, we calculate the weighted average unit price of the entire stocks, and then multiply it with Sales Qty to calculate the COGS. So, with this method, the COGS will be $960 and the ending stocks will be $840.

Thus, you can compare the results and decide on the method according to your financial situation, goals, legal regulations, product type, economical conjuncture, etc.

4. Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a formula to find the best order quantity that keeps inventory management costs as low as possible, taking into account both the cost of ordering and the cost of holding inventory.

Businesses can use the EOQ formula to find the best balance between the costs of placing orders and the costs of keeping inventory on hand. Companies can cut down on unnecessary stock, avoid running out of items, and improve cash flow by figuring out the EOQ.

- D is the annual demand for the product (units per year).

- S is the ordering cost per order (cost per order).

- H is the holding or carrying cost per unit per year.

With EOQ formula, you can find the best order quantity that keeps total inventory costs as low as possible, which includes the costs of ordering and holding. The EOQ formula helps companies figure out how much to order each time that will save them the most money.

So, this method works best for companies that have steady demand, and it can be added to inventory management systems to make the ordering process more efficient and automated.

5. Safety Stock

Safety stock is the extra inventory that is kept on hand in case of stock-outs due to changes in demand or problems in the supply chain. So, this method makes sure that there is always enough inventory to meet demand that comes up out of the blue.

If your market is too sensitive about switching to other suppliers, you should better to have safety stocks.

6. Six Sigma in Inventory Management Techniques

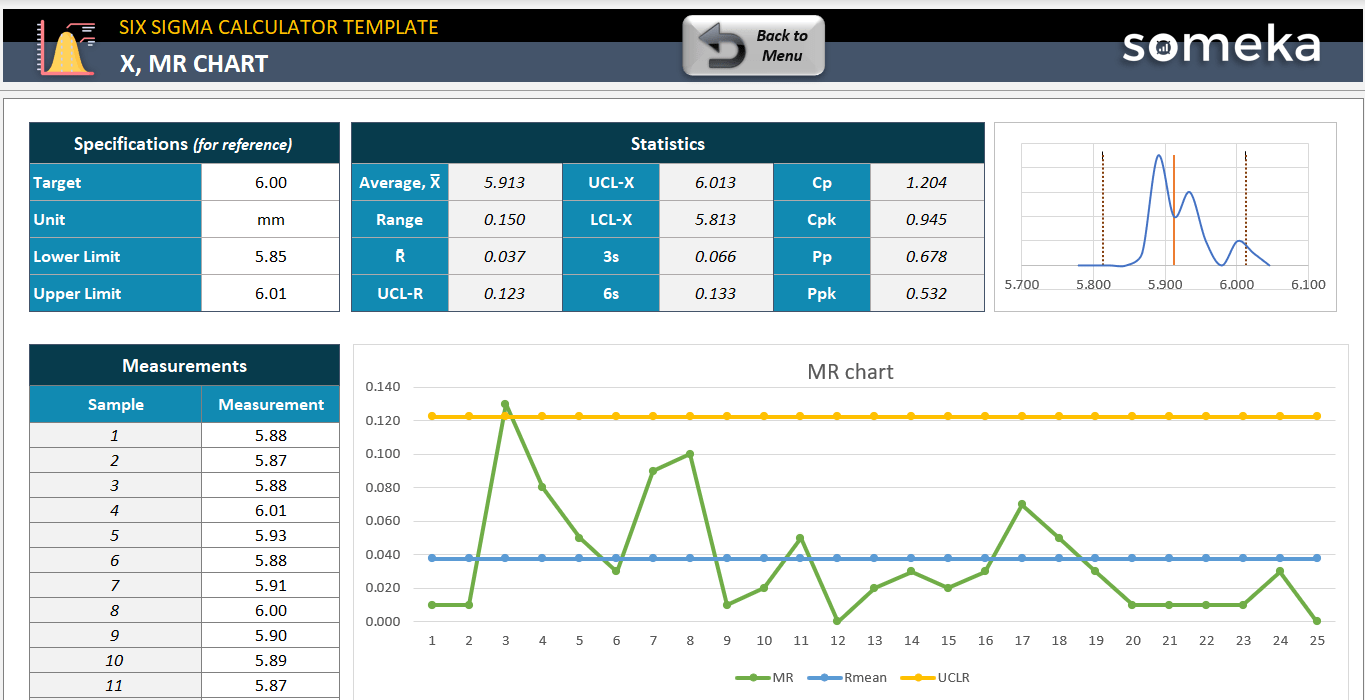

Six Sigma is a method based on data that aims to make business processes better by getting rid of errors and reducing variation. When it comes to managing inventory, Six Sigma techniques help companies be more accurate and efficient by finding and getting rid of the reasons why mistakes and inconsistencies happen in the process.

>> Download Six Sigma Calculator Template

This method uses careful statistical analysis to track and boost operational performance, which eventually saves money, raises quality, and makes customers happier. Companies can improve their overall business performance, lower their inventory levels, and speed up their supply chains by using Six Sigma.

7. Drop shipping

Drop shipping is a way for stores to manage their inventory where they don’t keep products in stock but instead send customer orders and shipping information to a third-party supplier, who sends the goods directly to the customer.

This method cuts down on the need to store inventory, the cost of doing so, and the risk of running out of stock or having too much of it.

Drop-shipping lets companies sell many different items without having to buy a lot of stock all at once. Thus, this makes it a good choice for online stores that want to grow quickly but don’t have a lot of money to spend. To make sure deliveries happen on time and customers are happy, though, you need strong relationships with your suppliers and order processing systems that work well.

8. PAR Levels

Periodic Automatic Replenishment (PAR) levels are set levels of inventory for each item that will cause it to be reordered. So, when stock drops below these levels, an automatic reorder is made to bring it back up to the PAR level.

Also, this method makes sure that there are always enough of the most important things without having too many. PAR levels are often used in fields like healthcare and hospitality where supplies need to be available all the time.

By keeping the right amount of inventory on hand, businesses can keep their carrying costs low, avoid running out of essential products, and make sure they always have access to them.

9. Reorder Point Formula

The reorder point formula calculates the specific level of inventory at which a new order should be placed.

>> Download Supply Order Planning Template

So, this technique ensures that inventory is reordered before it runs out, considering the lead time and average daily usage. S, you should create the purchase orders when your stock levels comes down to the reorder point.

10. Perpetual Inventory Management

With perpetual inventory management, the amount of inventory is always being checked and changed as transactions happen. Perpetual inventory systems use technology like barcode scanners, RFID tags, and inventory management software to update inventory counts automatically every time an item is sold, bought, or returned.

Actually, this is different from periodic inventory systems, which only update records every so often. So, the businesses can use this method to get accurate, up-to-date information on their inventory levels, which helps them make smart choices about reordering, stocking, and sales strategies.

By always showing the status of inventory, perpetual inventory management helps avoid running out of stock, cut down on extra stock, and boost overall efficiency. This method works especially well for companies that do a lot of transactions and want to connect their inventory management to other business tasks like accounting and sales.

IV. How to track my Inventory?

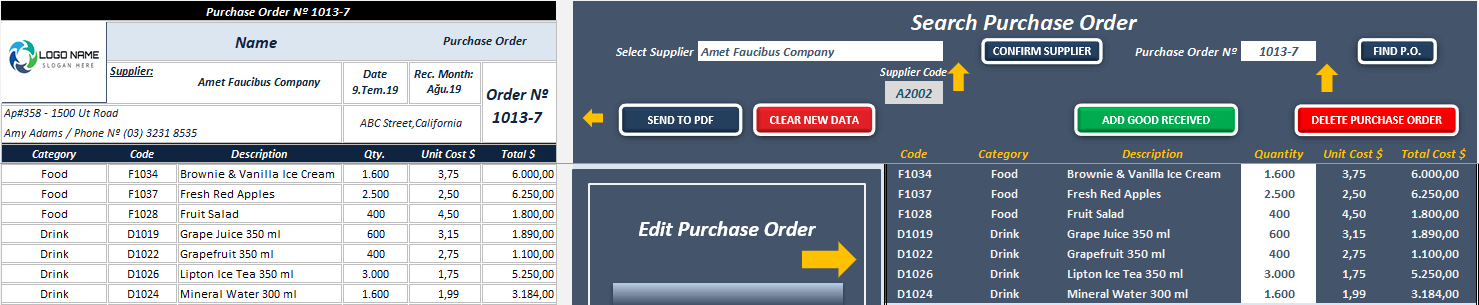

Lastly, whichever strategy or method you decide, you should set up a system to track your inventory. Indeed, you can use software or just create an inventory spreadsheet to monitor and calculate your inventory value and levels dynamically.

Here comes Someka’s Stock and Inventory Tracker template to help you organize all your stock in and out process.

>> Download Stock and Inventory Tracker

So, available in Excel, this template provides you a cost-effective and easy-start inventory management tool:

- List your items

- Record your purchases and sales

- Monitor your dashboard for stock movements

It’s that easy. Additionally, this is an editable and printable template, that you can customize according to your needs and use in your presentations. Additionally, you can also download inventory excel templates for other stock management needs, such as count sheets, abc analysis, or sku generator, etc.

V. Extra Tips on Inventory Management Techniques

Also, there some frequently asked questions (FAQ) for inventory management techniques. So we’ll also try to answer them:

-

What are the methods for managing inventory?

The most common methods for inventory management are Just-In-Time (JIT), ABC Analysis, FIFO-LIFO, Economic Order Quantity (EOQ), safety stock, Safety Stock, Reorder Point Formula, Six Sigma, Drop shipping, PAR (Periodic Automatic Replenishment) and Perpetual Inventory Management. So, each technique is suitable for a different reason and can be adapted to fit the needs and circumstances of a business.

-

How should I best keep track of my inventory?

The best way to keep track of inventory depends on the type of business and how it works. However, You can mostly achieve the best results by using a mix of techniques, such as EOQ to determine the best order quantity, keeping a safety stock, and categorizing inventory using ABC analysis. Also, using software for inventory management can also automate and speed up a lot of these tasks.

-

What is the most common way to keep track of inventory?

The FIFO method is the most common way to keep track of inventory. A lot of people use FIFO because it works with the way inventory naturally moves, making sure that older items are leaving the stocks first. Also, this method is especially important for businesses that deal with goods that go bad quickly or have expiration dates.

-

What’s the Difference Between LIFO and FIFO?

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two different ways to figure out how much an inventory is worth. FIFO means that the oldest items in stock are leaving the stocks first, which is great for goods that go bad quickly. LIFO means that the most recent inventory is leaving the stocks first, which can help lower taxable income when prices are going up. You should choose between FIFO or LIFO according to your the business’s financial plan and the type of inventory.

VI. Conclusion: Inventory Management Techniques

We have tried to give a collection of key inventory management techniques in this article. With all having pros and cons, it is important to clearly understand the dynamics to choose the best option or options for your company.

Any business that sells physical goods needs to be able to manage its inventory well in order to be successful. Different methods, like just-in-time (JIT), ABC analysis, FIFO, LIFO, EOQ, safety stock, and the reorder point formula, each have their own benefits and can differ to fit the needs of a business.

Finally, using these methods along with an inventory management software can give you a big edge in today’s competitive market.

Hope you have enjoyed our article!

Recommended Readings:

The Objectives of Inventory Management

Standard Work Essentials: Optimizing Your Business Operations and Lean Manufacturing

Can Excel Track Inventory? How to keep track of Inventory in Excel?