What’s SKU Number? Do we really need SKUs?

In this article, we will discuss the definition of SKU number, its purpose, why it is needed, its pros and cons, and also SKU best practices. We’ll try to share our business insights on stock-keeping unit concepts.

Table Of Content

1. What’s SKU?

2. What if we do not use SKU Numbers?

3. Where we use SKU numbers?

4. SKU Best Practices

5. Key Takeways

1. What’s SKU?

Let’s start first with the definition of SKU.

What is an SKU, and from what source did it come? Why is something like this needed?

SKUs are essentially used to track our products easily, identify the exact product we are referring to, and avoid making incorrect or erroneous product selections because of slight variations.

It’s basically just a short code. You can use codes such as 1, 3, 5, A, B, 13, AB, 14, and so on to identify your products. Definetely, there are some guidelines for creating SKU number, and we will talk about some best practices in later sections.

Let’s give an example to better understand SKU numbers.

Assume that you own a company that sells one hundred different kinds of goods. Knowing precisely which product you are referring to is important when selling these items, stocking them, billing clients, or having conversations with them.

If you have only 5-10 products, you may internally categorize your products as the red long-legged chair, the blue long-legged chair, the blue short-legged chair, etc. Within the organization, these are simple to identify. But it gets harder to track products as there are more of them, especially for outside parties.

Assigning SKUs to your products is essential, especially if you are managing inventory in a warehouse.

Despite the apparent simplicity and logic of this practice, we observe that many businesses do not follow it. Some of the businesses we’ve worked with on custom development projects manage hundreds of product lines without giving them individual codes.

As a result, managing a company without SKUs is difficult.

![]()

2. What if we do not use SKU Numbers?

SKU’s may seem easy to create. But after all, there are also some costs, like time and labor. Let’s explore the systematization process and weigh the pros and cons of SKUs. Do the advantages of using SKUs outweigh the disadvantages? Let’s investigate this.

Do we need systematization?

These days, systematization and automation are highly discussed subjects, particularly in business contexts. But first, there are a few things we should clarify. Is the result worth the effort we put into systematizing our business processes? Because this is a serious matter.

There is a cost associated with increasing systematization in our processes, which is essentially a reduction in flexibility.

We must decide on the level of flexibility and level of systematization in light of business culture and strategy.

Do we need SKUs?

Now going back to the subject of SKUs.

A critical step in this systematization process is the use of stock keeping units, or SKUs.

However, in what context is it required? We’ll discuss this in three sub-guidelines.

-

Service Companies:

You might not need to give your services SKUs if your business sells services, such as a consultancy.

-

Limited Number of Products:

Is it still necessary to assign SKUs if you are selling products but only have a small quantity of them? In our opinion, it’s advantageous since your product range might expand in the future, and being prepared is wise. But it’s still a strategic decision. Say you’re selling just three large products named Chair, Table, and Couch, and you refer to them as such and don’t want to change that. In this case, not using SKUs might be okay.

-

Great Number of Products:

However, the third case is when you have a lot of products in your portfolio. In that scenario, using SKUs will help you be more organized.

3. Where we use a SKU number?

Moving on to our third topic, let’s look at some examples and determine exactly where and how SKUs are used.

We’ll demonstrate concret SKU applications with a few examples.

Data analysis:

SKUs are used in the distribution and computation of sales and expenses for your products, including unit and total costs. When determining which sales originate from a particular product or sub-product group, SKUs are a great resource.

![]()

Let’s use pivot tables in Excel as a clear and understandable example for everyone. When you use pivot tables for data analysis, you can see how disparities in product/person or name entries can cause data discrepancies, which is a major issue for businesses.

SKUs allow you to do precise analysis, which is especially useful if you have a large number of products.

ERP and CRM Systems:

These kinds of CRM or ERP systems, such as SAP, Oracle, or Salesforce) need you to enter your products by specifying their SKUs. If not, these systems have trouble matching products to their backend database.

Inventory Management:

Finding the right product match is crucial for stock management, warehouse management, and inventory tracking. SKUs are therefore also heavily utilized in these sectors.

Customer Relations:

We also use SKUs to accurately identify products during customer interactions. SKUs are used so that people outside of your company, including customers and third parties, can quickly and accurately determine which of your products they are talking about.

There may be variations in terms and names for your products over time. But the particular technical product in question is identified by what we refer to as a Unique Code, or SKU. This is reassuring to your customers as well as making it more clear and convenient.

4. SKU Best Practices

We are now in the fourth section of our article. We have already discussed the need for SKUs, their history, whether businesses should adopt them, how they fit into the systematization process, their advantages and disadvantages, and their application scenarios. We’ll now examine the best practices for assigning SKUs to our products.

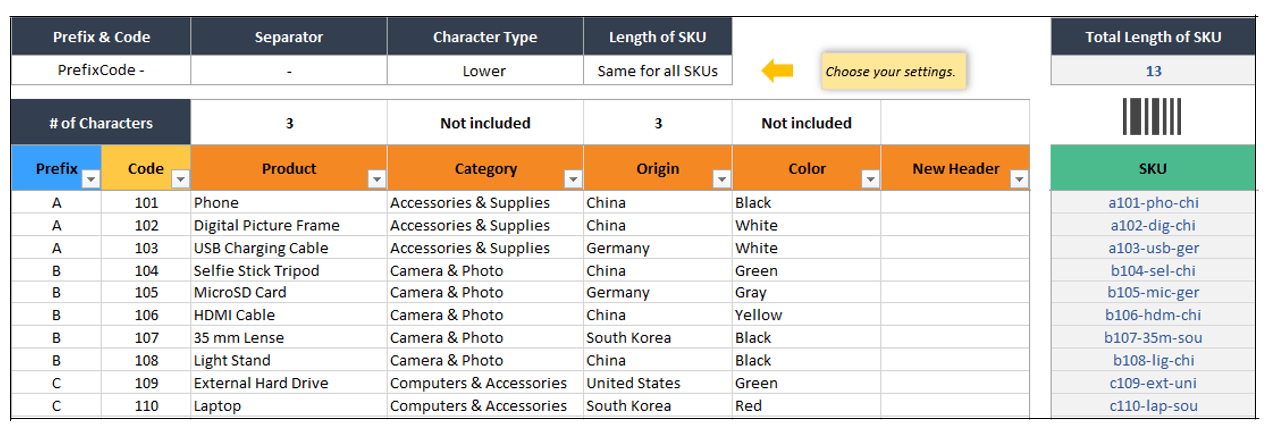

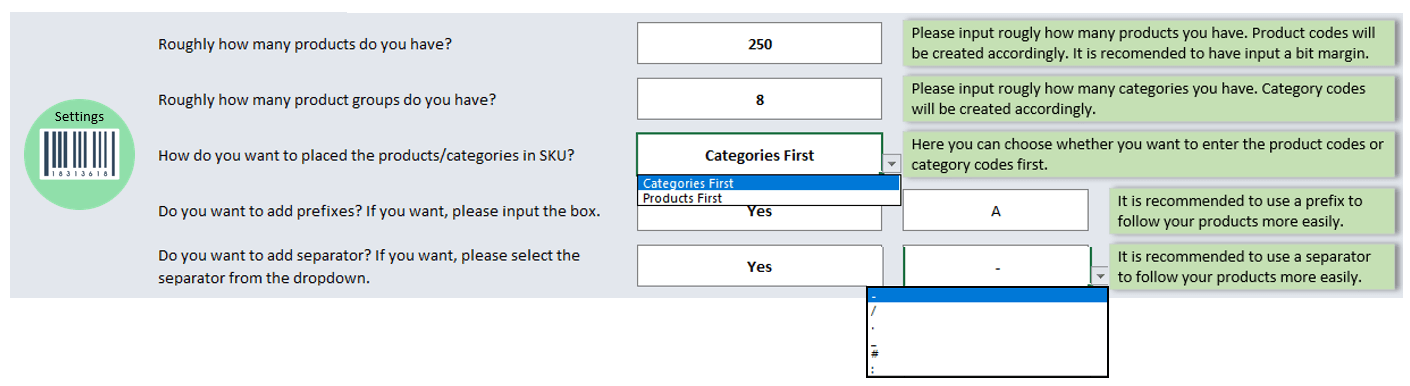

– This is an example of SKU elements from SKU Generator Template by Someka –

Unique Codes:

It’s important to ensure that the SKUs you assign to your products are not only unique now but will remain unique in the future. If you use a limited set of letters or numbers, you might eventually run into limitations.

Ideal SKU Number Length:

A SKU generally consists of five to ten characters. Thus, you shouldn’t overly restrict yourself, but you should also stay away from superfluous length. For example, a 10-character SKU format might be overly complicated for you if you only have 100 products total.

Smart Coding

Smart Coding or Smart SKUs mean that your SKUs may have a letter at the beginning, a number in the middle, or a symbol at the end. There could be a meaning behind these letters for you.

SKUs beginning with ‘A’, for example, might stand for one product group, and those beginning with ‘B’, for another. This can make running your internal operations easier.

So, many large companies, particularly those that oversee hundreds or thousands of products, prefer smart SKU approach. You may need special SKU generator tools to create smart SKUs according to your product groups, types or attributes.

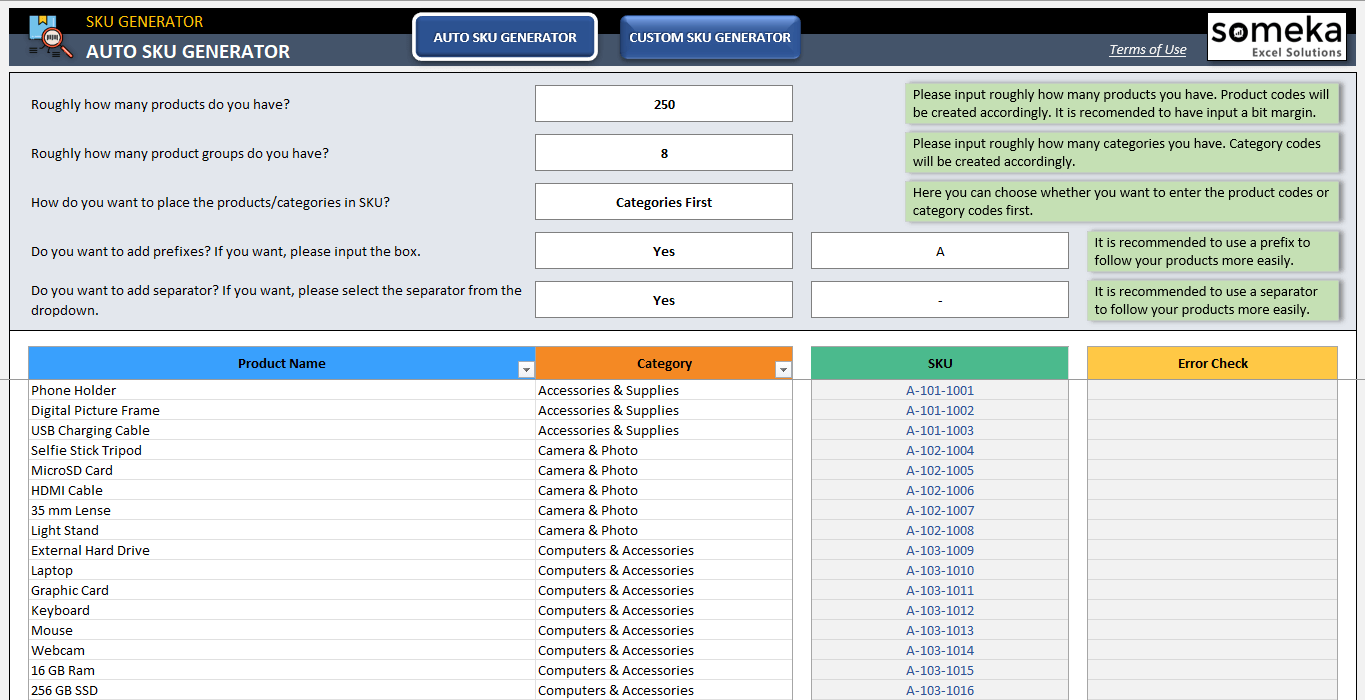

We have also created a unique SKU Generator in Excel for our users. If you prefer to keep your list online, you can also download Google Sheets SKU Generator from our portfolio:

– A screenshot from SKU Generator Template by Someka –

With this tool, you can use Auto SKU Generator to create SKU number units in bulk, or prefer Custom SKU Generator for more customized stock keeping unit creation.

Lastly, here’s a 60-second tutorial on Someka SKU Generator:

5. Key Takeways on SKU Number Concept

In conclusion, SKUs are an important and necessary aspect for your company if your business model is suitable and requires it. Here are the keypoints from our insights:

- Consider the pros and cons of SKU’s and decide on if you really need them

- Implement a clean and evergreen SKU system

- Take into account SKU best practices

Hope you enjoy our article about this crucial tool in product and inventory management.

Recommended Readings:

Product Pricing: Methods, Strategies and Expert Tips

The Objectives of Inventory Management: Techniques, Challanges and Process in Detail!